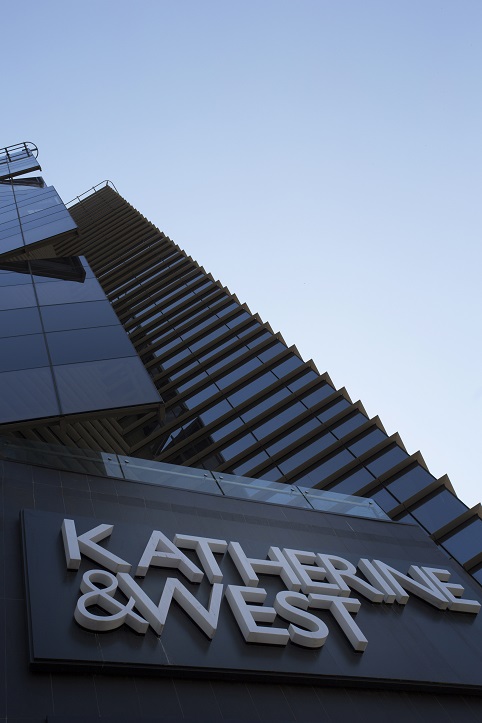

TAL supplies rapid-setting and flexible adhesive system for wall and floor tile installations at Katherine & West

Katherine & West, an office development on the corner of Katherine and West Streets in the Sandton Gate precinct and TAL supplied ancillary products and adhesives for an installation of porcelain tiles which would fill 10 000m².

The building stands eight stories tall and carries a modern design with its triangular shape, striking glass façade and corner, a prominent black tiled feature wall to which its signage is secured, which faces the intersection of Katherine and West Streets. LYT Architecture designed the building and it was developed by Barrow Properties. It consists of approximately 19 000m² sectional title office space and seven luxury penthouse apartments.

TAL supplied TAL Goldstar 6 adhesive and TAL Bond, a latex additive was used in the installation of tiles on the exterior facade, interior lobby, lift shaft walls, reception area and in the bathrooms. TAL Goldstar 6, being a rapid-setting adhesive, was perfect for a fast-track installation such as this as it allows traffic on the tiled area, depending on site and ambient conditions, after six hours was able to be trafficked after only a few hours, while offering enough flexibility to withstand building and thermal movement and exposure to the elements. Being a grey powder-adhesive, TAL Goldstar 6 is suitable for fixing porcelain, ceramic and dark-coloured granite and marble tiles to walls and floors in interior and exterior installations.

The tiled feature wall on the outside of the building especially required a flexible and water-resistant installation as the cladding is exposed to temperature fluctuations and weather conditions which result in the expansion and contraction of the installation. For this reason, water in the adhesive mixture was replaced with TAL Bond, a modified latex additive, to enhance the bond strength and flexibility of the tile installation.

On the exterior walls of the building, black matt porcelain tiles in a 600x600mm format were installed and mechanical supports were installed at 1.8m intervals. Tile panel movement joints were created at 1.8m x 3m intervals to allow for movement in the installation, and TAL Goldstar Sealmaster 1000, a single component permanently flexible polyurethane joint sealant, was used to seal the tile panel movement joints, adding to the instalment’s longevity. In the lobby, 400x800mm matt porcelain tiles in light grey were used for the floor tiling installation and the lift shaft walls were tiled with a 600x600mm grey matt porcelain tiles. Mechanical supports were installed every three metres. On the first floor, the reception area features a light grey 400x800mm gloss floor tiles. The bathrooms were tiled using 300x600mm charcoal coloured matt porcelain tiles. All of the external balconies were tiled with 300x600mm matt porcelain tiles, TAL Goldstar 12, a quick-setting, high-strength adhesive was mixed with TAL Bond to improve the flexibility and water-resistance of the tile adhesive.

[Back]

blog comments powered by Disqus