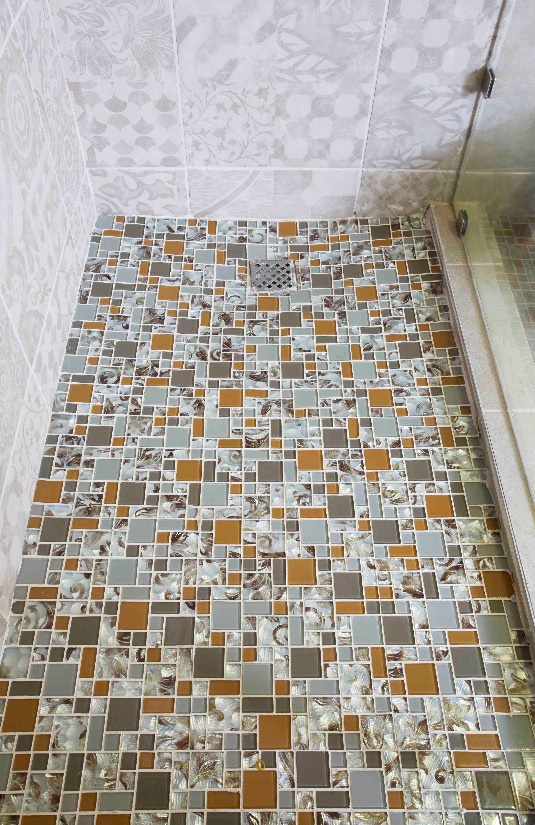

How to successfully install glass mosaics onto a shower floor

Update 2018-09-10

For centuries, mosaics have provided a beautiful decorative element to all types of structures. Shower mosaics are particularly popular, and here TAL provides useful tips and guides on how to apply glass mosaics to a shower floor.

Mosaics are assembled as sheets, either paper-faced – glued face-down onto paper or plastic, or mesh-backed – bed-side down onto a synthetic mesh backing or small tabs. Paper-faced mosaics are preferable, as they allow full contact with the adhesive.The backing mesh should be a water-resistant synthetic fabric like nylon – not cotton or paper. It should be compatible with the adhesive, and not weaken when exposed to moisture. With mesh-backed mosaics, the fabric or tabs and bonding should cover less than 25% of the back of each mosaic tile, or tessera, to enable adequate adhesive contact. Damaged tesserae should be replaced.

Mosaics are assembled as sheets, either paper-faced – glued face-down onto paper or plastic, or mesh-backed – bed-side down onto a synthetic mesh backing or small tabs. Paper-faced mosaics are preferable, as they allow full contact with the adhesive.The backing mesh should be a water-resistant synthetic fabric like nylon – not cotton or paper. It should be compatible with the adhesive, and not weaken when exposed to moisture. With mesh-backed mosaics, the fabric or tabs and bonding should cover less than 25% of the back of each mosaic tile, or tessera, to enable adequate adhesive contact. Damaged tesserae should be replaced.

TAL’s quick-setting MOSAICFIX adhesive is ideal for installing mesh-backed glass mosaics onto a shower floor, as it is light in colour. Glass tiles tend to be see-through, and darker adhesives may affect the aesthetic finish of the installation adversely by making the colour of the tiles appear different. We therefore recommend using the Super White variant.

TAL’s quick-setting MOSAICFIX adhesive is ideal for installing mesh-backed glass mosaics onto a shower floor, as it is light in colour. Glass tiles tend to be see-through, and darker adhesives may affect the aesthetic finish of the installation adversely by making the colour of the tiles appear different. We therefore recommend using the Super White variant.

Note: Note that properly detailed and installed waterproofing is essential when tiling a shower. Look at How to Waterproof a Shower.

Step 1. Begin by priming the surface, ensuring it is in good condition, and clean and dry, with a moisture content of less than 5%. Brush a layer of TAL FLOOR PRIMER onto the surface, and leave to dry completely, before preparing the adhesive mix.

Step 1. Begin by priming the surface, ensuring it is in good condition, and clean and dry, with a moisture content of less than 5%. Brush a layer of TAL FLOOR PRIMER onto the surface, and leave to dry completely, before preparing the adhesive mix.

Step 2. In the meantime, plan the layout of the mosaic sheets and cut them to fit around the waste.

Step 2. In the meantime, plan the layout of the mosaic sheets and cut them to fit around the waste.

Tip: For enhanced flexibility and water resistance, it is recommended that the adhesive water mix be replaced with TAL BOND. This is important in installation areas that will be exposed to water, heat and humidity. Add TAL MOSAICFIX to the liquid and mix well to a creamy, lump-free consistency. Let it stand for three minutes and stir again.

Step 3. Once mixed well, apply the adhesive to the surface in a solid bed of 4 mm to 6 mm, working in small areas of a square metre at a time.

Step 3. Once mixed well, apply the adhesive to the surface in a solid bed of 4 mm to 6 mm, working in small areas of a square metre at a time.

|

Step 4. Bed the mosaics immediately, pressing them firmly into the adhesive. Use a wooden beating block or rubber grouting float to tap them in and create a level surface. Using tile spacers between the individual mosaic sheets will maintain the joints. |  |

Step 5. Allow the adhesive to squeeze through the joints between the mosaics to form the grout and, if necessary, fill in any low areas in the joints with extra adhesive. |

Step 6. Clean the excess adhesive off the face of the mosaics gently with a lightly dampened sponge, and leave to dry for a few hours.Work carefully to ensure that the mosaic installation is not disturbed, and that the glass mosaics are not scratched during application and cleaning. Polish the mosaic tiles with a dry cloth to remove any grout haze.

Step 7. Apply a silicone sealant to all the perimeter joints.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

Designed to be 100% compatible, using the TAL range of products ensures fully guaranteed multi-level tiling systems from a single source. TAL products are manufactured in South Africa to suit local climatic conditions.

If you are in any doubt, contact the TAL Technical Advisory Service on 0860 000 TAL (825), email taltech@tal.co.za. Alternatively, employ the services of an experienced and skilled mosaic tiling contractor.

[Back]

blog comments powered by Disqus